INSPECTIONS

Call Us Today! (310) 327-5740

Call Us Today! (310) 327-5740

INSPECTIONS

MAGNETIC PARTICLE INSPECTION (MPI)

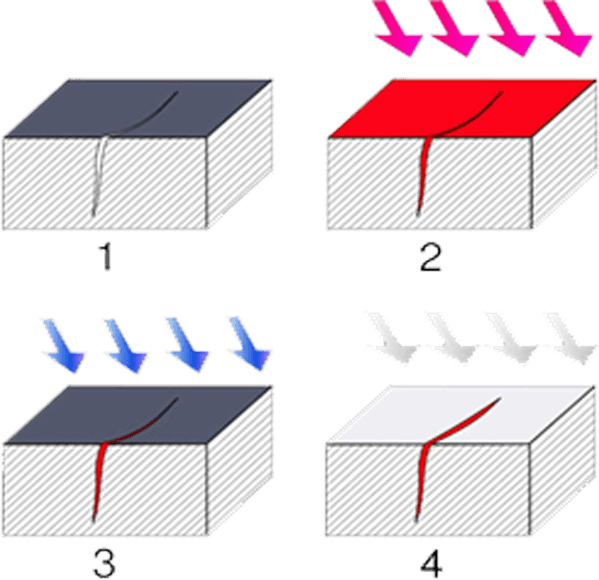

Magnetic particle inspection processes are non-destructive methods for the detection of defects in ferrous materials. They make use of an externally applied magnetic field or DC current through the material, and the principle that the magnetic susceptibility of a defect is markedly poorer (the magnetic resistance is greater) than that of the surrounding material.

DYE PENETRANT INSPECTION (DPI)

Dye penetrant inspection (DPI), also called liquid penetrant inspection (LPI), is widely applied in today’s oil and gas industries and this low-cost inspection method is used to locate surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). Penetrant may be applied to all non-ferrous materials, but for inspection of ferrous components magnetic-particle inspection is preferred for its subsurface detection capability. DPI is used to detect casting and forging defects, cracks and leaks in new products, and fatigue cracks on in-service components.

CALL US TODAY AT ♦ (310) 327-5740

CONTACT INFORMATION

Sonic Plating Company

Ryan Granath Owner / Operator

Tina Mc Vay / Dir. of Operations

Carmen Anquiano / QA Manager

Louie Gonzalez/ Shop Manager

ADDRESS

1930 W Rosecrans Ave

Gardena, CA 90249

PHONE

BUSINESS HOURS

Monday through Friday:

7:30 a.m. to 4:00 p.m.

EMAIL

BUSINESS ASSOCIATIONS

Share

Tweet

Share

Mail

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy